Smooth geomembrane

A smooth geomembrane is a type of geosynthetic material with a relatively smooth and glossy surface.

These geomembranes are typically made from high-density polyethylene (HDPE) or other synthetic polymer materials, featuring a smooth exterior surface.

The geomembrane used in biogas power generation projects is typically high-density products.

High-density polyethylene (HDPE) is a common material for geotextile membranes in such projects due to its high impermeability,

chemical resistance, and mechanical strength, making it well-suited for preventing the permeation of gases and liquids in biogas applications.

Funtions in Biogas Power Generation Projects

326798.webp)

1. Impermeability Ensures Gas Containment:

Smooth geomembrane, with its exceptional impermeability, serves as a reliable barrier to contain biogas within designated areas such as storage tanks and digesters.

This impermeability prevents the escape of biogas into the surrounding environment, ensuring optimal gas collection and utilization for power generation.

2. Preventing Liquids Seepage:

In biogas projects, liquids produced during the fermentation process need to be effectively contained.

Smooth geomembrane acts as a robust liner to prevent seepage of liquids into the ground,

protecting the soil and groundwater from potential contamination. This feature is crucial for maintaining the integrity of the biogas production infrastructure.

3. Durability in Harsh Environments:

Biogas facilities often operate in challenging environmental conditions. Smooth geomembrane,

known for its durability and resistance to various environmental factors, provides long-lasting protection. Whether facing temperature variations,

chemical exposure, or UV radiation, this geomembrane ensures consistent performance, contributing to the sustainability of the biogas power generation system.

4. Ease of Installation:

Smooth geomembrane is designed for ease of installation, allowing for efficient and cost-effective deployment in biogas projects.

Its smooth surface facilitates straightforward placement and sealing, reducing the time and labor required for installation.

This contributes to the overall cost-effectiveness of biogas power generation endeavors.

5. Environmental Protection:

Smooth geomembrane not only safeguards the biogas infrastructure but also plays a role in environmental protection.

By preventing the seepage of liquids and gases, it ensures that potential contaminants are contained within the designated areas, minimizing the ecological impact and promoting the sustainable operation of biogas power generation projects.

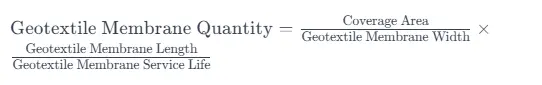

How to caculate the geofilm quantity

135097.webp)

he basic formula for calculating the quantity of geotextile membrane is:

Where:

The coverage area is the surface area that needs to be covered, determined based on project design.

Geomembrane width is the selected width of the geotextile membrane.

Geofilm length is the length of the specific coverage area.

Geomembrane service life refers to the expected duration for the geotextile membrane to maintain its performance typically determined from technical specifications provided.

It is important to note that this is a simplified calculation formula, and actual calculations may require more detailed engineering assessments based on the complexity of the project.

Construction attentions

154672.webp)

In biogas power generation projects, the construction of geomembranes is a critical step that impacts the overall quality and reliability of the entire project. Here are some important considerations during the construction of geomembranes in biogas projects:

1,Site Preparation: Ensure the construction site is leveled, cleaned, and free of any sharp or pointed objects that could damage the geomembrane before its installation.

2,Geomembrane Selection: Choose the appropriate type of geomembrane for the biogas project, considering its impermeability, chemical resistance, mechanical strength, and other relevant characteristics. Ensure the geomembrane meets project design and specification requirements.

3,Seam Treatment: Proper treatment of geomembrane seams is crucial. Ensure seams are robust, sealed, and resistant to leakage. Common seam methods include hot wedge welding, chemical bonding, etc., and the choice depends on the geomembrane material and project requirements.

4,Installation Methods: Select the appropriate geomembrane installation methods, such as laying, securing, and connecting, according to project requirements. Ensure the geomembrane is properly placed without wrinkles or looseness.

5,Protection Measures: Implement protective measures on the construction site to prevent damage to the geomembrane during the construction process. Avoid direct damage from sharp tools, heavy machinery, etc.

6,Construction Environment: Pay attention to the climate and weather conditions during construction. Take appropriate measures in extreme temperatures, high winds, heavy rain, etc., to ensure smooth geomembrane construction.

7,Quality Inspection: Conduct quality inspections during construction, including random checks on seams, surface inspections of the geomembrane, etc. Detect problems promptly and take corrective actions to ensure the quality of geomembrane construction.

8,Recording and Documentation: Record key processes during geomembrane construction, including seam treatment, installation methods, inspection results, etc., to create detailed documentation. This is crucial for project acceptance and future maintenance.

9,Professional Construction Team: Hire an experienced and professional construction team specializing in geomembrane installation. They should be familiar with relevant processes and operating standards to ensure efficient and high-quality geomembrane construction.

These considerations help ensure the smooth construction of geomembranes in biogas power generation projects, guaranteeing the reliability and long-term stability of the project.

Haoyang Invironmental's advantages

623524.webp)

Equipment Advancements

1,Our production line has the ability to produce single and double-sided rough surface geomembranes

demonstrates an advanced domestic production process.

2,The capability to produce 10-meter wide geomembranes represents advanced domestic production equipment.

3,Utilization of a melt pressure monitoring system allows real-time monitoring of screw extruder pressure conditions, ensuring product quality.

4,The entire machine adopts PLC (Programmable Logic Controller) and touchscreen control, achieving a high level of automation.

Certifications

1,Film Blowing Air Ring Cooling Device (Patent Certificate): This device efficiently cools geomembranes using natural air temperatures,

enhancing product qualification rates and addressing cooling challenges during geomembrane production.

2,Film Blowing Equipment Film Storage Rack (Patent Certificate): This innovative solution addresses the technical challenge of storing geomembranes during production,

improving the inherent indicators of the product.

3,Biaxial Winder (Patent Certificate): This design resolves the issue of double winding for special coil orders, saving labor and increasing production efficiency.

4,Limiting Device for Winding Machine (Patent Certificate): This design restricts product deviation, ensuring it returns to the normal winding position,

achieving a corrective effect. It guarantees product appearance, provides convenience for the packaging process, and solves existing technical issues.

These advancements and patented solutions contribute to the overall efficiency, quality, and innovation in geomembrane production, showcasing a commitment to cutting-edge technology and problem-solving within the industry.

FAQ

1: What is the primary function of smooth geomembrane in biogas power generation projects?

Smooth geomembrane serves as an impermeable barrier, preventing the escape of biogas and liquids, ensuring efficient containment for optimal power generation.

2: How does smooth geomembrane contribute to environmental protection in biogas projects?

By preventing the seepage of liquids and gases, smooth geomembrane contains potential contaminants within designated areas,

minimizing ecological impact and promoting sustainable biogas power generation.

3: What are the key considerations when selecting smooth geomembrane for biogas projects?

Consider impermeability, chemical resistance, mechanical strength, and ease of installation. Ensure the chosen geomembrane aligns with project design and specifications.

4: Can smooth geomembrane withstand harsh environmental conditions commonly found in biogas facilities?

Yes, smooth geomembrane, known for its durability, resistance to environmental factors, and longevity,can withstand challenging conditions such as temperature variations and chemical exposure.

5: How does the installation of smooth geomembrane contribute to the overall cost-effectiveness of biogas power generation projects?

The smooth surface facilitates straightforward installation, reducing time and labor costs.

Its impermeability and longevity also contribute to long-term cost savings by minimizing maintenance and replacement needs.

631.webp)

378.webp)

609.webp)

117.webp)

574.webp)

585.webp)

523.webp)